Quality assurance of product production

7Chemtech ensures the consistency and reliability of our products through ongoing quality control measures. We are committed to providing high-quality products to meet customer needs and expectations.

- ISO, NSF, SGS and other quality certifications

- Strict management at every stage

- Quality testing from start to finish

- Innovation and sustainable development strategy

How 7Chemtech Guarantees Superior Quality

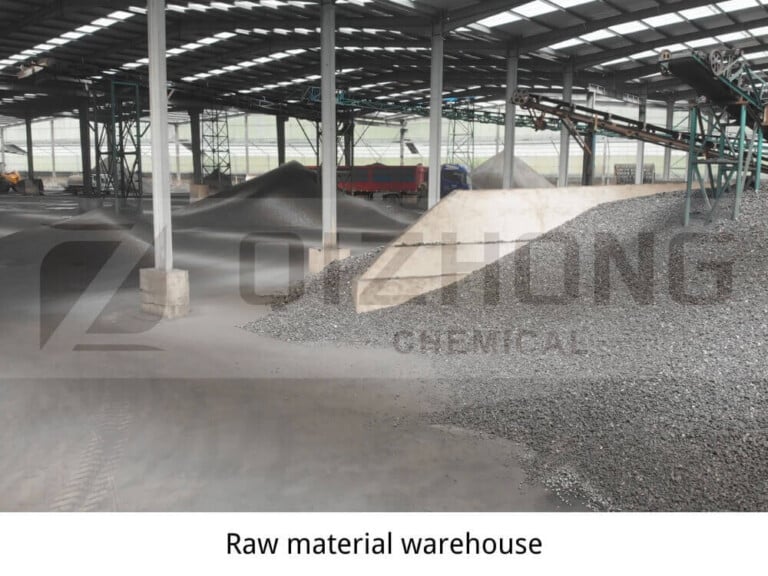

High standards in selecting raw materials

At 7Chemtech, we understand that the journey to superior activated carbon begins with the finest raw materials. We source our raw materials from reputable suppliers who share our dedication to environmental sustainability and consistent quality. Each batch of raw material is subjected to rigorous testing to ensure that it meets our stringent purity standards, guaranteeing that only the best ingredients are used in our production process.

Employee training and competencies

Our commitment to quality extends to our team of professionals. We invest heavily in employee training programs to ensure that each member of our staff is not only skilled but also up-to-date with the latest advancements in activated carbon production. Our training modules cover everything from safety practices to quality control procedures, ensuring that our team works efficiently and effectively to produce the highest quality activated carbon.

Stringent Testing Procedures

Quality control is at the heart of our operations. We employ a comprehensive series of stringent testing procedures at every stage of production to ensure that our activated carbon products meet the highest standards. These tests include but are not limited to, iodine number testing, molasses number testing, and ash content analysis. Our in-house laboratory is equipped with state-of-the-art equipment to carry out these tests with precision and accuracy.

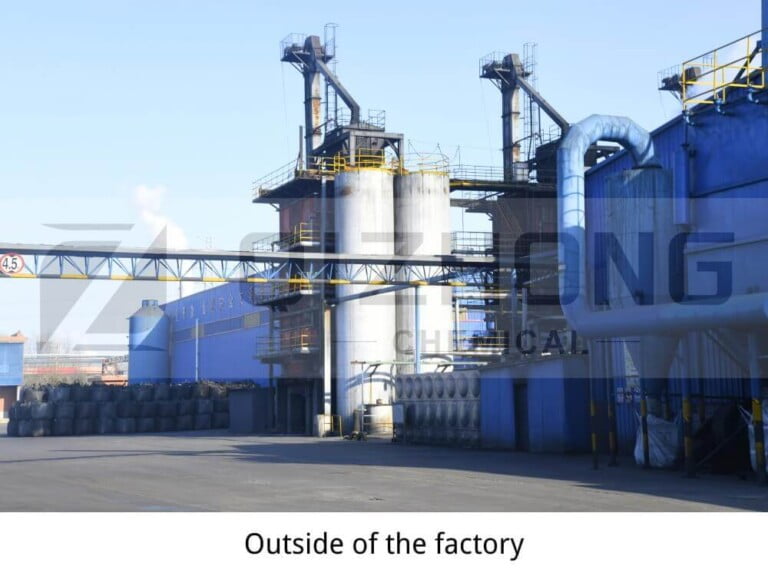

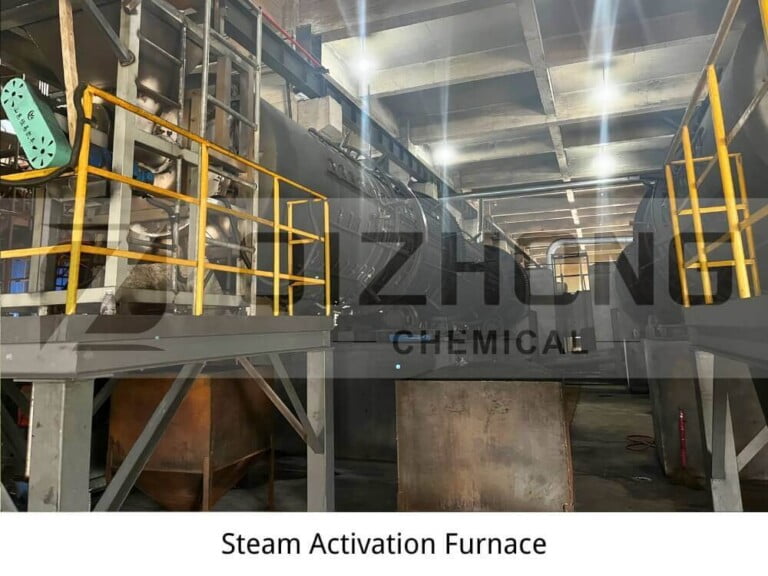

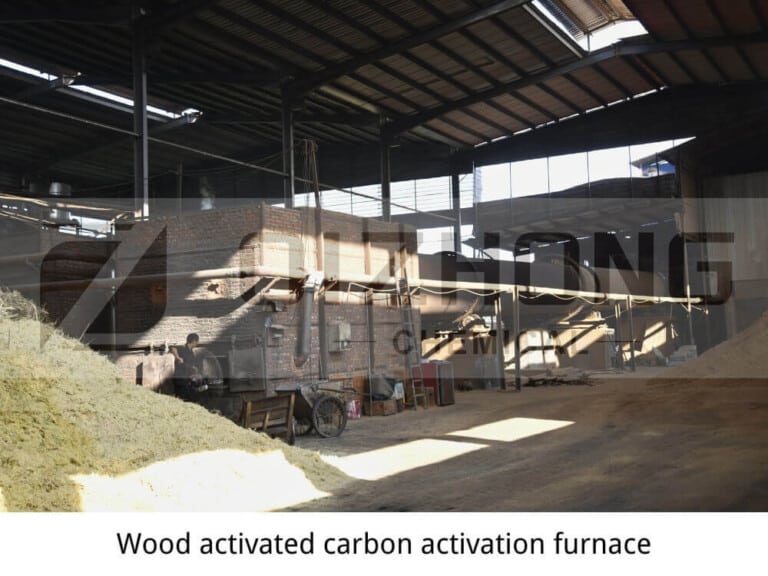

Advanced equipment and technologies

Innovation is key to maintaining our leadership in the activated carbon market. We leverage cutting-edge equipment and technology to enhance our production capabilities and increase efficiency. Our facilities are fitted with advanced machinery that ensures consistent product quality and enables us to meet the diverse needs of our clients. By continuously upgrading our technology, we stay ahead of industry trends.

Specific Practices for Quality Assurance

Pre-production

Raw Material Inspection

Prior to production, we meticulously inspect our raw materials for consistency and purity. This involves a series of checks such as moisture content analysis, carbon content verification, and material size grading. Our suppliers are required to meet our high standards, and we only proceed with materials that pass our strict acceptance criteria.

Preparation and Calibration

Our equipment is thoroughly prepared and calibrated before any production begins. This ensures that all machinery operates within specified parameters, delivering consistency in our production process. Calibration is conducted by certified technicians using calibrated instruments, adhering to international standards.

In-production

Continuous Monitoring

Throughout the production process, we maintain continuous monitoring to ensure that each phase meets our quality benchmarks. Parameters such as temperature, pressure, and reaction times are closely watched and adjusted in real-time to maintain optimal conditions.

In-process Sampling and Testing

Regular sampling and testing occur during production to monitor the quality of the activated carbon as it is being produced. This includes tests for adsorption capacity, surface area, and pore structure. Any deviations from our quality standards are immediately addressed by our production team.

Final production

Final Product Testing

Once production is complete, our activated carbon undergoes a final series of comprehensive tests. These tests are designed to confirm that the product meets all specifications such as particle size distribution, hardness, and bulk density. Only after passing these rigorous tests is the product packaged for distribution.

Packaging Integrity

We ensure that the packaging of our activated carbon provides adequate protection against contamination and damage during transportation. Our packaging materials are selected for their durability and are subject to strict quality control checks.

Traceability and Documentation

Each batch of our activated carbon is fully traceable, with detailed records maintained from raw materials to final product delivery. This documentation provides our customers with the assurance of quality and the ability to trace the product back through every step of its production.

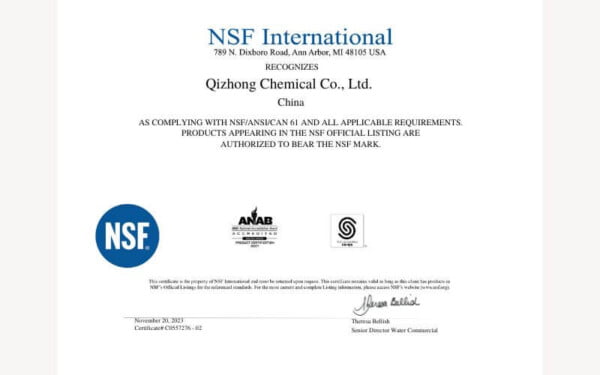

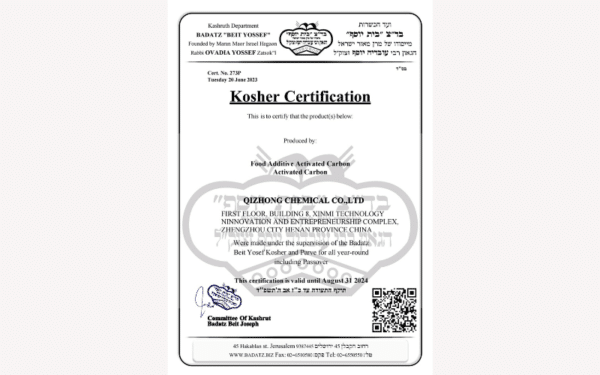

Quality Certifications

We leave no stone unturned to ensure that our activated carbon production meets the highest industry standards. To demonstrate our commitment to quality and excellence, we have actively pursued and obtained accredited certification from relevant organizations.

- ISO 9001:2015

- NSF

- KOSHER

- HALAL