Introduction of catalyst support media

In the realm of chemical reactions and industrial processes, catalysts play a crucial role in accelerating reactions, improving yields, and reducing energy consumption. However, the effectiveness and longevity of catalysts heavily depend on the medium on which they are supported. This blog post aims to shed light on the significance of catalyst support media, their types, and their impact on catalytic performance.

What are Catalyst Support Media?

Catalyst support media, also known as catalyst carriers or substrates, refer to solid materials that serve as a foundation for catalysts in chemical reactions and industrial processes. They provide a stable surface on which catalysts can be immobilized or dispersed, enabling efficient catalytic activity. These media offer key benefits such as thermal resistance, structural stability, and a high surface area, all of which contribute to enhanced catalytic performance. By facilitating catalyst immobilization and optimizing reaction conditions, support media play a critical role in maximizing the efficiency and effectiveness of catalysts in diverse chemical applications.

Types of Catalyst Support Media

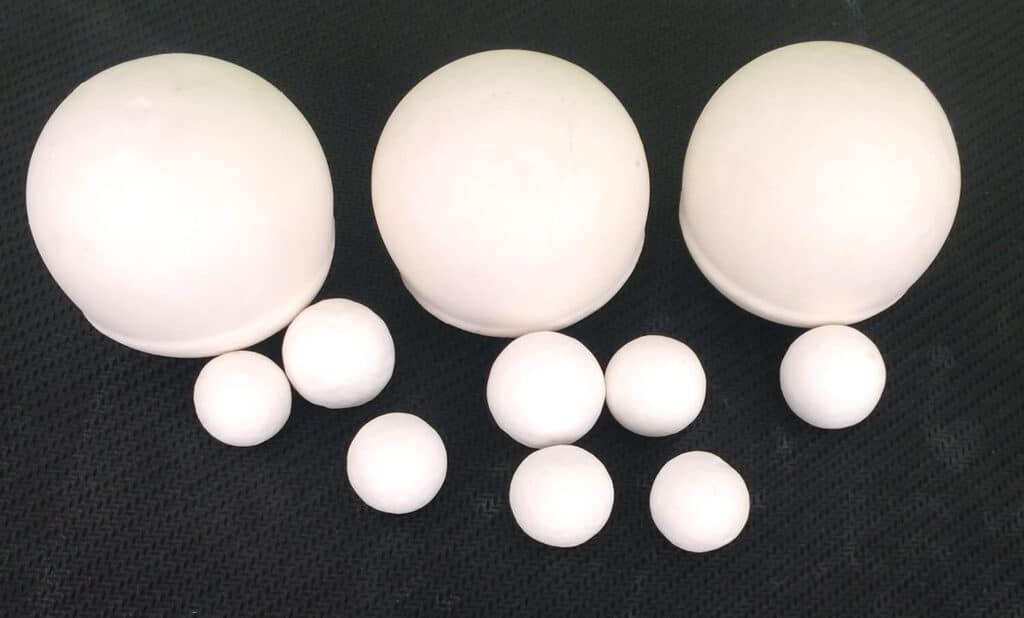

Alumina Balls

Alumina balls, composed of aluminum oxide (Al2O3), are widely utilized as catalyst support media. They possess high mechanical strength, excellent thermal stability, and a large surface area. Alumina balls find applications in catalytic processes such as refining, petrochemical production, and environmental remediation.

Molecular Sieves

Molecular sieves are crystalline materials with well-defined pore structures. They exhibit selective adsorption properties based on molecular size and shape. Molecular sieves as catalyst support media are employed in processes requiring precise separation and purification, such as gas drying, air separation, and petroleum refining.

Activated Carbon

Activated carbon is a highly porous form of carbon with an extensive internal surface area. It offers exceptional adsorption capacity and is commonly used as a catalyst support medium in gas-phase reactions, water treatment, and air purification processes. Activated carbon provides effective mass transfer and helps enhance catalytic activity.

Ceramic Balls

Ceramic balls, manufactured from materials like alumina, zirconia, or silica, serve as catalyst support media due to their superior thermal stability, chemical inertness, and mechanical strength. These characteristics make ceramic balls suitable for catalyst support in high-temperature reactions, heterogeneous catalysis, and catalytic reforming processes.

Each of these catalyst support media possesses distinct properties and advantages that make them suitable for specific applications. The selection of the appropriate support media depends on factors such as the nature of the catalytic reaction, desired catalytic activity, stability requirements, and compatibility with reactants and products.

Impact of Catalyst Support Media

The choice of catalyst support media significantly influences the overall catalytic performance. Here are some key considerations:

Surface Area and Pore Structure

Catalyst support media with high surface areas and well-defined pore structures facilitate better dispersion of catalyst particles and enhance the exposure of active sites, leading to increased reaction rates.

Thermal Stability

Catalytic reactions often involve high temperatures. Therefore, selecting a support media with excellent thermal stability ensures the catalyst’s longevity and prevents its deactivation due to structural changes.

Chemical Inertness

The support media should be chemically inert to prevent unwanted reactions or catalyst poisoning, ensuring that the catalyst remains active and selective throughout the process.

Mechanical Strength

Catalyst supports should possess sufficient mechanical strength to withstand the operational conditions, including pressure and mechanical stress, to maintain structural integrity.

Conclusion

Catalyst support media serve as critical elements in optimizing catalytic reactions and industrial processes. Their ability to provide stability, enhance dispersion, improve mass transfer, and tailor selectivity greatly impacts the overall performance of catalysts. By carefully selecting the appropriate support media, researchers and engineers can maximize catalytic efficiency, extend catalyst lifetimes, and achieve desired reaction outcomes.

As a leading provider of catalyst support media solutions, our company is committed to delivering high-quality products that meet the diverse needs of industries worldwide. Whether you require tailored selectivity, improved dispersion, or enhanced stability, our team of experts is dedicated to assisting you in selecting the ideal catalyst support media for your specific applications. Contact us today to explore how our support media solutions can elevate your catalytic processes to new heights.