You may have heard of granular activated carbon when we talk about purifying water, improving air quality, or treating those hard-to-treat pollutants. Or about some unfamiliar areas, such as gold recovery in gold mines and decolorization and decontamination in the food and beverage industry. Maybe you’re feeling a bit confused and it all sounds a bit complicated, but don’t worry, we’re here to answer all your questions.

In this blog, we’re going to take a lighter tone and explore what granular activated carbon is, why it’s so amazing, and where you can find it.

Part 1. Definition of Granular Activated Carbon

First, let’s understand what activated carbon is and its different types and materials, including coal based granulated activated carbon and coconut granular activated carbon. Keep reading!

What is Granular Activated Carbon?

Granular Activated Carbon is an excellent adsorbent material that exists in the form of small particles, with a wide range of particle sizes (typically around 4 mesh – 80 mesh). This material is primarily used to adsorb and remove impurities and harmful substances from liquids or gases, and it can be applied to purify water sources, improve air quality, and play a crucial role in various application sectors.

What are the types of granular activated carbon?

When studying granular activated carbon, it is important to understand its different types. The two main types of granular activated carbon are as follows:

Coal based granular activated carbon

As the name suggests, this type of activated carbon is prepared from coal (bituminous coal, anthracite coal, lignite, etc.). Coal-based granular activated carbon is an excellent adsorbent material and is available in small, hard granules. It is known for its excellent adsorption performance and cost-effectiveness. It efficiently adsorbs various pollutants from liquids or gases, including chlorine residual, organics, odors, colors, heavy metals, etc.

Coal-based granular activated carbon finds wide applications in many fields, including domestic water treatment, industrial wastewater treatment, air purification, food and beverage industry, as well as medical and pharmaceutical sectors. It not only improves water and air quality but also contributes to environmental protection, making it an indispensable material.

Coconut shell based granular activated carbon

In comparison to coal-based granular activated carbon, this type is prepared from coconut shells. Coconut shell is a renewable resource, hence considered as a more environmentally friendly choice. Coconut shell-based granular activated carbon is made from high-quality coconut shells through high-temperature heating and steam activation processes. It has a high surface area and microporous structure, which makes it highly suitable for water purification and improving indoor air quality.

Apart from extensive usage in household water filters and air purifiers, coconut shell-based activated carbon is also employed in various industrial sectors, such as precious metal recovery (gold, copper, etc.), pharmaceuticals, chemicals, etc.

These are the two main types of granular activated carbon, and depending on your specific application needs, you can choose the appropriate type. Whether you are new to this field or a professional buyer, this information will help you better understand the diversity and uses of granular activated carbon. Let’s compare them in the table below for a better understanding.

| Perspective | Coal-Based Activated Carbon | Coconut Shell Activated Carbon |

|---|---|---|

| Raw Material Source | Coal | Coconut Shell |

| Production Process | High-temperature carbonization and activation | High-temperature carbonization and activation |

| Surface Area | Moderate | Highly developed |

| Microstructure | Developed mesopores | Developed micropores |

| Ash Content | Relatively high | Relatively low |

| Adsorption Performance | Excellent | Excellent |

| Environmental Friendliness | Low | High |

| Price Comparison | Moderate | Higher |

| Main Application Areas | Industrial wastewater treatment Drinking water purification Municipal water treatment Sugar decolorization Food & beverage Pharmaceuticals Air purification Waste gas treatment Catalyst carrier | Home water treatment Air purification Gold recycling Food & beverage Pharmaceuticals Catalyst carriers |

Part 2: Production process of granular activated carbon

We have already discussed the concept and types of granular activated carbon. Now we will explore the process of producing granular activated carbon, including the changes that occur from selecting the raw materials to the final product. Let’s get started.

Preparing granular activated carbon is a complex process that involves multiple steps and treatment methods. Here are the general steps for producing granular activated carbon:

Step 1: Raw material selection

The first step is to choose the appropriate raw material. Common raw materials include coal, nutshell, and coconut shells, among others. Different raw materials will influence the characteristics of the final activated carbon product.

Step 2: Crushing and grinding

The raw material needs to be crushed and ground to obtain particles suitable for making activated carbon. In the case of coal-based granular carbon, in addition to conventional raw coal crushed carbon, there is also pressure agglomerated carbon to improve the strength of the activated carbon.

Step 3: Carbonization

Carbonization is the process of thermally decomposing the raw material under oxygen-deficient and high-temperature conditions (300 – 500 °C) to form a porous carbon structure. During carbonization, most of the non-carbon elements such as hydrogen and oxygen are removed as volatile gas products through the cracking process of the raw material.

Step 4: Activation

Activation is a crucial step in the preparation of activated carbon. The purpose of activation is to remove tar substances and decomposition products accumulated in the pore structure during carbonization by using steam or chemicals. This process expands the pores and creates micropores to increase the pore volume or specific surface area of the carbonized material and produce highly adsorbent activated carbon.

Step 5: Sieving and particle size selection

The prepared particles need to be sieved to select the desired size. The commonly used particle sizes for water filtration cartridges are 8-30 mesh, 12-40 mesh, and 30-70 mesh.

Step 6: Retreatment

For specific applications, activated carbon may undergo additional treatments, including regular washing, and acid washing, to improve purity, reduce ash content, and heavy metal levels. Chemical treatments such as impregnation solutions and precious metals may also be used to achieve a wider range of applications.

Step 7: Packaging

Packaging is typically done in bags or drums to ensure the storage and transportation of the product. Commonly used packaging includes 25kg bags and 500kg bulk bags.

Step 8: Quality control

Quality control is crucial throughout the preparation process. Each step needs to be strictly monitored and controlled to ensure that the final product meets expected standards in terms of quality and performance.

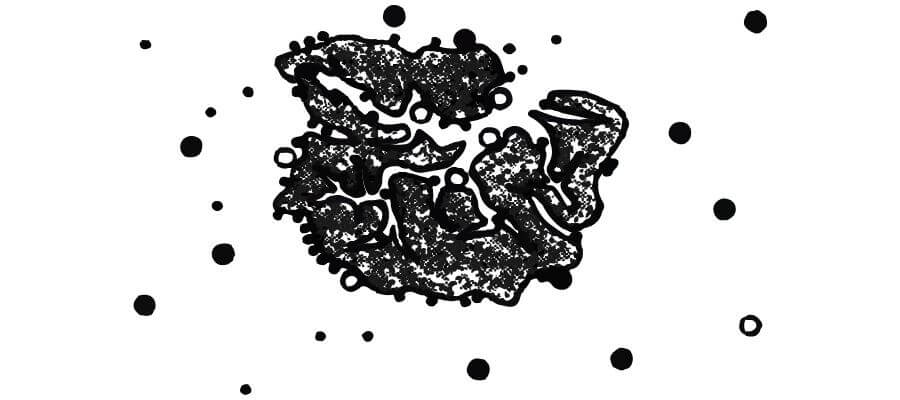

Have you understood the process so far? Next, I will show you some photos of our factory production workshop. Enjoy!

Part 3: Parameters and Principles

In the previous two parts, we have learned about the concept, types, and production process of granular activated carbon. Now, let’s delve into the working principles and performance parameters of granular activated carbon.

Working Principles of Activated Carbon

The working principles of granular activated carbon are based on its adsorption capabilities, which involve both physical and chemical adsorption. Physical adsorption refers to the attraction of molecules to the surface of the carbon, while chemical adsorption involves the bonding of molecules with the chemical functional groups on the surface of the activated carbon. Activated carbon provides a highly developed pore structure that greatly increases its surface area, thus enhancing its adsorption capacity.

Performance Parameters of Activated Carbon

Performance parameters are important indicators for evaluating the adsorption capacity and quality of granular activated carbon. Let’s take a closer look at these parameters:

- Iodine Value: The iodine value is one of the indicators used to evaluate the adsorption capacity of activated carbon. It reflects the adsorption capacity of activated carbon for iodine per unit mass. A higher iodine value indicates a stronger adsorption capacity. Typically, the iodine value of granular activated carbon ranges from 800 to 1200 mg/g.

- Particle Size: The particle size refers to the size of the granular activated carbon and is usually represented by mesh size. Smaller particle size generally indicates higher adsorption capacity. The particle size of granular activated carbon typically ranges from 4 to 80 mesh. Commonly used particle sizes include 4-8 mesh, 4-12 mesh, 6-12 mesh, 8-16 mesh, 8-30 mesh, 12-40 mesh, 20-50 mesh, 30-60 mesh, 40-80 mesh, etc.

- Bulk Density: The bulk density of granular activated carbon refers to the mass per unit volume of the carbon and is usually expressed in g/cm³. The bulk density of granular activated carbon typically ranges from 0.4 to 0.6 g/cm³.

- Moisture Content: The moisture content refers to the amount of water present in the activated carbon. It can affect the adsorption performance and quality of the carbon. Typically, the moisture content of granular activated carbon is below 5%.

- Ash Content: The ash content refers to the amount of inorganic residue present in the activated carbon and is an important indicator of its quality. Typically, the ash content of granular activated carbon is below 10%.

These are the working principles and performance parameters of granular activated carbon. The selection and control of these parameters are crucial for ensuring the performance and quality of activated carbon. In practical applications, it is important to choose the appropriate granular activated carbon based on specific requirements to achieve the best purification results. Let’s now explore the applications of activated carbon!

Part 4: Applications

Let’s delve into the multiple application areas of granular activated carbon, whether it be improving drinking water quality, treating wastewater, purifying municipal water sources, or playing a role in gas purification, gold recovery, food and beverage industry, pharmaceuticals, and catalysts, granular activated carbon has unique application potential.

Drinking Water Purification

Granular activated carbon filters is widely used in drinking water treatment to remove odor, organic compounds, residual chlorine, and heavy metals. It improves the taste and quality of water, ensuring the safety of drinking water.

Wastewater Treatment

In industrial wastewater treatment, granular activated carbon is used as an adsorbent to remove organic compounds, color, and pollutants from wastewater. This helps purify wastewater and reduce environmental pollution.

Municipal Water Purification

Used in municipal water treatment plants to improve the quality of tap water. It effectively removes organic compounds, chlorine, and odor, ensuring access to healthy tap water.

Gas Purification

Granular activated carbon is widely used in indoor air purifiers and industrial gas purification systems to remove harmful gases, odors, and pollutants, providing fresh indoor air.

Gold Recovery

In gold mining and recovery, granular activated carbon in the size range of 6-12 mesh is used as an adsorbent to help adsorb gold from gold-bearing solutions, and subsequent processing steps are used to extract the gold from the activated carbon.

Food and Beverage Industry

Granular activated carbon is used in food processing and beverage production to remove color, odors, impurities, and organic contaminants, ensuring the quality of food and beverages.

Pharmaceuticals

It is used in the pharmaceutical industry for the purification of medications and drugs, removing organic substances, impurities, and pigments. It is also used in toxicology treatment and emergency situations.

Catalyst Support

Due to its high surface area and porous structure, granular activated carbon is commonly used as an ideal support for catalysts, promoting chemical reactions.

These are the main applications of granular activated carbon in various industries, its versatility and outstanding adsorption capacity make it an important tool for environmental protection, water quality improvement, product purification, and resource recovery. Whether it is for environmental protection or improving the quality of life, granular activated carbon plays a crucial role.

FAQ

What is the difference between granular activated carbon and regular charcoal?

Granular activated carbon and regular charcoal, although both derived from carbon material, have completely different preparation and applications. Granular activated carbon has a highly porous structure consisting of micro-pores and meso-pores, making it an excellent adsorbent used for removing pollutants from water and air. In contrast, regular charcoal is mainly used for applications such as barbecue and outdoor survival, and it has lower adsorption capacity and is not suitable for purification applications.

How do I determine which type of granular activated carbon I need?

Determining the type and specifications of granular activated carbon needed usually requires considering the specific requirements of the application. Factors such as the type of pollutants, water quality issues, and particle size requirements can be taken into account. You can consult our team of experts who would be happy to assist you.

How to properly store granular activated carbon?

Granular activated carbon should be stored away from exposure to moisture and high temperatures. It is best to store it in a dry, cool, and well-ventilated area, and avoid direct sunlight. Sealed containers or packaging also help prevent issues with moisture absorption and degradation of the adsorption performance of granular activated carbon.

Does granular activated carbon have an expiration date?

Granular activated carbon does not have a specific expiration date, but over time, its adsorption performance may weaken. Regular inspections and proper storage are key to ensuring its effectiveness.

What is the difference between granular activated carbon and powdered activated carbon?

Granular activated carbon is typically in granular form and possesses a porous structure. Its particle size typically ranges from 0.5 mm to 5 mm. Granular activated carbon is better suited for large-flow water treatment systems, such as household filters and industrial wastewater treatment. Due to their larger size, granular activated carbon experiences lower pressure drop loss and has a longer lifespan.

Powdered activated carbon is in the form of fine powder, with particle sizes typically ranging from 50 micrometers to 200 micrometers. It has a faster adsorption rate and is suitable for small cartridge filters and specific applications such as drinking water purification, pharmaceutical preparations, and gas phase adsorption.

What is the bulk density of granular activated carbon?

The bulk density of granular activated carbon refers to the weight of the carbon particles per unit volume under certain conditions. This parameter is often expressed as mass per unit volume. It is important when selecting the appropriate granular activated carbon, as it is related to factors such as pressure drop loss, flow rate, and bed stability. Different suppliers may have granular activated carbons with different bulk densities, so this factor should be considered when choosing a product.